Discover the Advantages of Aluminum Casting in Modern Production

Aluminum casting has actually become a critical process in contemporary production. Its light-weight yet durable nature presents significant advantages for various markets. The capability to accomplish complex layouts and keep limited tolerances contributes to its allure. aluminum casting. Additionally, the cost-effectiveness and environmental benefits make it a sustainable option. As manufacturers seek cutting-edge solutions, the function of aluminum casting proceeds to evolve. What particular applications and benefits await expedition in this vibrant field?

Solid yet lightweight: The Benefits of Aluminum

Many materials are made use of in production, aluminum stands out due to its amazing combination of light-weight buildings and outstanding stamina. This special quality makes aluminum an optimal choice for numerous applications, especially in industries such as auto, aerospace, and building and construction. Its low density permits for simpler handling and transportation, adding to decreased power usage throughout production and setting up procedures.

Additionally, aluminum's strength-to-weight proportion is remarkable, enabling manufacturers to produce durable elements without including unnecessary mass. This particular is especially useful in industries where weight decrease can result in improved fuel effectiveness and overall performance. In addition, aluminum's resistance to corrosion boosts the durability of items, even more strengthening its charm in modern-day manufacturing.

Inevitably, the lightweight yet solid nature of aluminum placements it as a favored product, fostering technology and effectiveness throughout numerous fields. Suppliers progressively identify that these advantages can cause substantial innovations in design and performance.

Precision and Intricacy in Layout

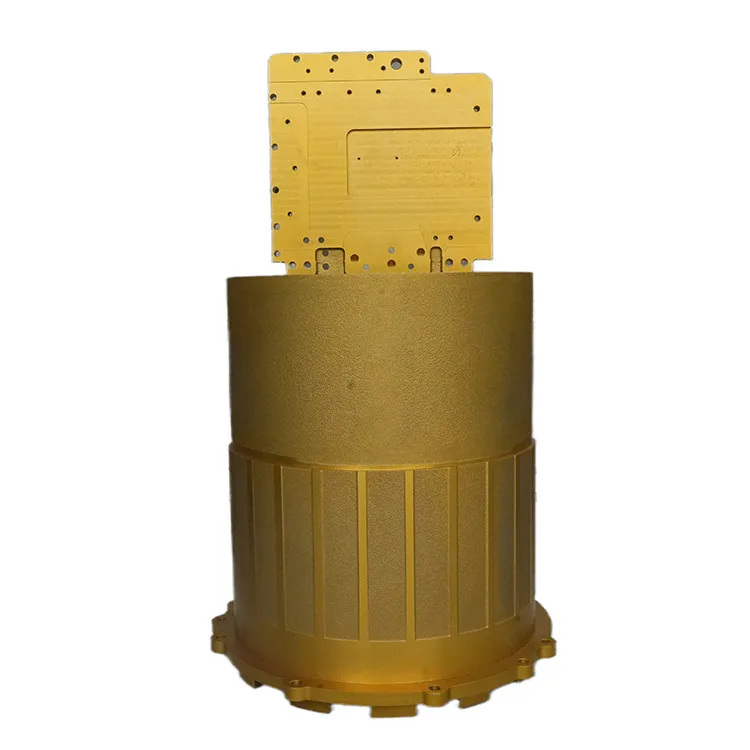

As suppliers welcome the capabilities of aluminum casting, they find new opportunities for precision and intricacy in style. This production procedure enables the development of complex forms and in-depth functions that standard techniques often struggle to achieve. The fluidness of liquified aluminum allows it to load intricate molds, resulting in components with tight tolerances and great surface finishes.

This precision is specifically useful in markets such as aerospace and automotive, where exact requirements are vital for performance and safety and security. Aluminum casting also accommodates ingenious designs that boost performance without compromising structural honesty.

Cost-Effectiveness and Efficiency

Cost-effectiveness and effectiveness are critical factors to consider for manufacturers exploring aluminum casting as a manufacturing approach. Aluminum casting deals significant expense benefits as a result of its lower material costs compared to various other metals (aluminum casting). The lightweight nature of aluminum lowers shipping and handling costs, and its excellent thermal conductivity enables for quicker cooling times throughout the casting process, improving total production rate

Aluminum's adaptability makes it possible for suppliers to create complicated forms and layouts, lessening the requirement for added machining or setting up. This streamlining of manufacturing not additional info just reduces labor costs but also shortens lead times, allowing companies to respond swiftly to market demands.

Additionally, the longevity and deterioration resistance of aluminum spreadings add to longer item life expectancies, minimizing substitute expenses in time. Consequently, manufacturers can achieve a balance of premium result and lowered functional costs, making aluminum casting a significantly appealing alternative in contemporary production.

Environmental Sustainability of Aluminum Casting

Aluminum casting attracts attention as an ecologically lasting manufacturing alternative, particularly because of its recyclability and reduced environmental footprint. The procedure enables the reliable use of aluminum, a product that can be reused indefinitely without shedding its properties. This characteristic substantially decreases the need for virgin aluminum, thereby saving all-natural sources and reducing energy intake connected with extraction and handling.

Applications Across Industries: From Automotive to Aerospace

While varied markets proceed to look for ingenious products for production, aluminum casting has actually verified to be a flexible solution across sectors such as vehicle and aerospace. In the automobile sector, aluminum castings add to light-weight vehicle layouts, improving gas efficiency and performance. Elements like engine blocks, transmission housings, and wheels take advantage of aluminum's strength-to-weight ratio.

Likewise, in aerospace, aluminum casting plays a considerable duty in creating intricate components that need high longevity and reduced weight. Airplane components such as brackets, touchdown gear, and structural structures use aluminum for peak performance and security.

The flexibility of aluminum casting enables it to cater check out here to various other markets, including customer electronic devices, aquatic, and industrial equipment. This convenience not only fulfills the particular needs of various applications however additionally supports recurring advancement in manufacturing procedures. Consequently, aluminum casting continues to be a principal in contemporary manufacturing throughout numerous markets.

Frequently Asked Inquiries

Just How Does Aluminum Casting Contrast to Various Other Metal Casting Processes?

Aluminum casting deals premium strength-to-weight ratios, faster cooling prices, and excellent deterioration resistance contrasted to other steel casting processes. These benefits make it suitable for different applications, boosting effectiveness and performance in production.

What Are the Regular Lead Times for Aluminum Casting Projects?

Regular preparation for aluminum casting tasks range from two to 8 weeks, depending upon factors such as complexity, order size, and manufacturing ability. Efficient planning can help decrease delays and improve job timelines.

Can Aluminum Casting Be Utilized for Intricate Styles?

Aluminum casting can certainly accommodate intricate designs. Aluminum Casting Company. Its fluidness enables comprehensive patterns and forms, making it ideal for complicated elements in various sectors. This adaptability boosts design freedom while preserving architectural integrity and performance

What Post-Processing Options Are Readily Available After Aluminum Casting?

Post-processing options for aluminum casting consist of machining, polishing, surface therapies, anodizing, and welding. These methods improve the coating, improve dimensional accuracy, and increase corrosion resistance, therefore maximizing the last item's performance and aesthetic allure.

Exactly How Do Temperature Level Adjustments Affect Aluminum Casting Quality?

Temperature changes significantly effect aluminum casting high quality by affecting fluidity, solidification rates, and potential issues. Quick air conditioning can cause boosted brittleness, while extreme warm may cause bending or insufficient filling of molds throughout casting.

Aluminum casting has emerged as an essential process in contemporary production. As producers welcome the capabilities of aluminum casting, they find brand-new avenues for precision and complexity in layout. Aluminum casting processes commonly produce less greenhouse gas exhausts compared to other metal casting methods. While diverse sectors proceed to seek innovative products for production, aluminum casting has actually shown to be a flexible remedy across industries such as vehicle and aerospace. In the auto industry, aluminum castings contribute to light-weight lorry layouts, enhancing gas efficiency and performance.